30 Apr 5 Complex 3D Printed Vacuum Forming Tools With A Unique Base

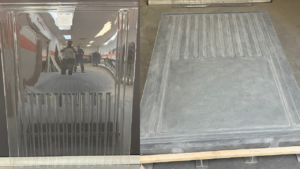

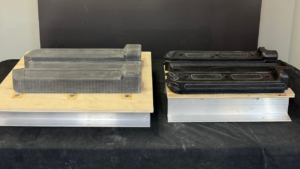

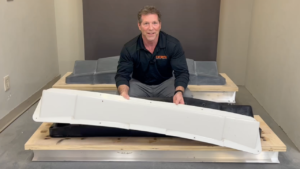

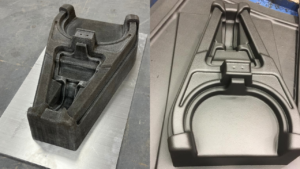

5 Complex 3D Printed Vacuum Forming Tools With A Unique Base These are 5 smaller 3D printed vacuum forming tools, all with complex designs and a unique base. The tools have a standard 100 RA surface finish, completed in 1.5 weeks ...