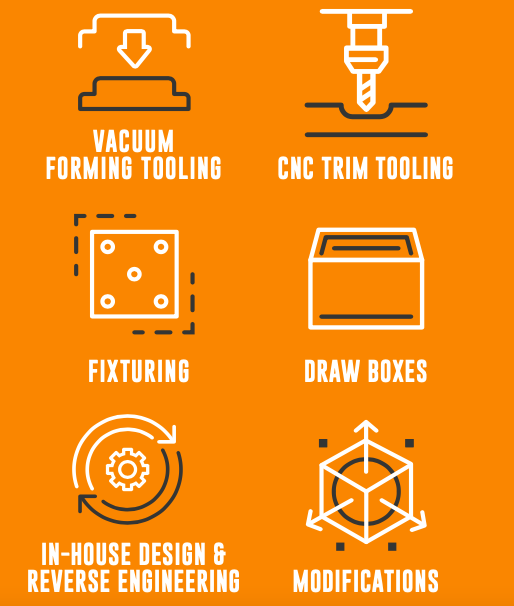

Catalysis 3D Printed Fixtures

Additive manufacturing has completely changed the way thermoformers – and OEMs – view tooling, in terms of production time, cost and quality. When compared to traditional metal tooling, Catalysis can 3D print tooling in half the time for half the cost while maintaining the same level of quality. Not only that, but 3D printing allows for the design of more complex tooling or low-to-medium volume production parts, removing constraints inhibited by traditional tooling design.

Benefits Of Catalysis 3D Printed Fixtures

All fixtures use the same 3D printing technology, have the same design in order to save cost & time and are delivered together. Since all of the tools are made at the same time, this allows for an easier, more efficient time saving streamline process.

CNC Trim Tool

QC Check Fixture

Assembly Fixture

Draw Boxes

trim tool

check fixture

CAT Website_Fixturing1

Screen Shot 2022-08-02 at 2.57.56 PM

Draw Box

- All tools use the same 3D printing technology

- Same design utilized to save cost & time

- All tools are made at the same time (don’t have to wait)

- Easier, more efficient, time saving streamline process

- Delivery of all tools together in less than 2 weeks

Manufactured in less time & less cost of traditional metal tooling

Our technology has allowed us to truly be a One-Stop-Shop for all of your tooling needs

Compared to Conventional Fixturing Methods

Metal Assembly Fixture

- Typically manufactured from aluminum

- Process can be very time consuming

- Expensive tooling costs

Ren / Wood Board

- Manufactured with laminated layers of wood

- Longer lead time