Founded on Experience

While working at Honda of America Manufacturing, Catalysis founders Darrell Stafford and Rick Shibko witnessed how much focus was on the reduction of product development schedules. The result was a negative impact on the reduction of tooling lead times, subsequently resulting in higher prototype tooling costs. With more new products being introduced all the time and the increasing frequency of model changes, the prototype tooling costs and lead times became a challenge to reduce.

Catalysis Additive Tooling was founded by utilizing the collective 60+ years of automotive engineering, tooling, and new model development experience of Stafford and Shibko. That experience combined with their 10+ years of Additive Manufacturing/3D Printing research allows us to offer our customers a complete solution to support their Development and Production needs.

Our talented team that we have built over the years is who turns the vision of Stafford & Shibko into reality. From designing each tool, printing, post processing and delivering the tools to the customer in a quick turnaround time, our team is what makes this possible.

Companies We Do Business With

Our Latest News

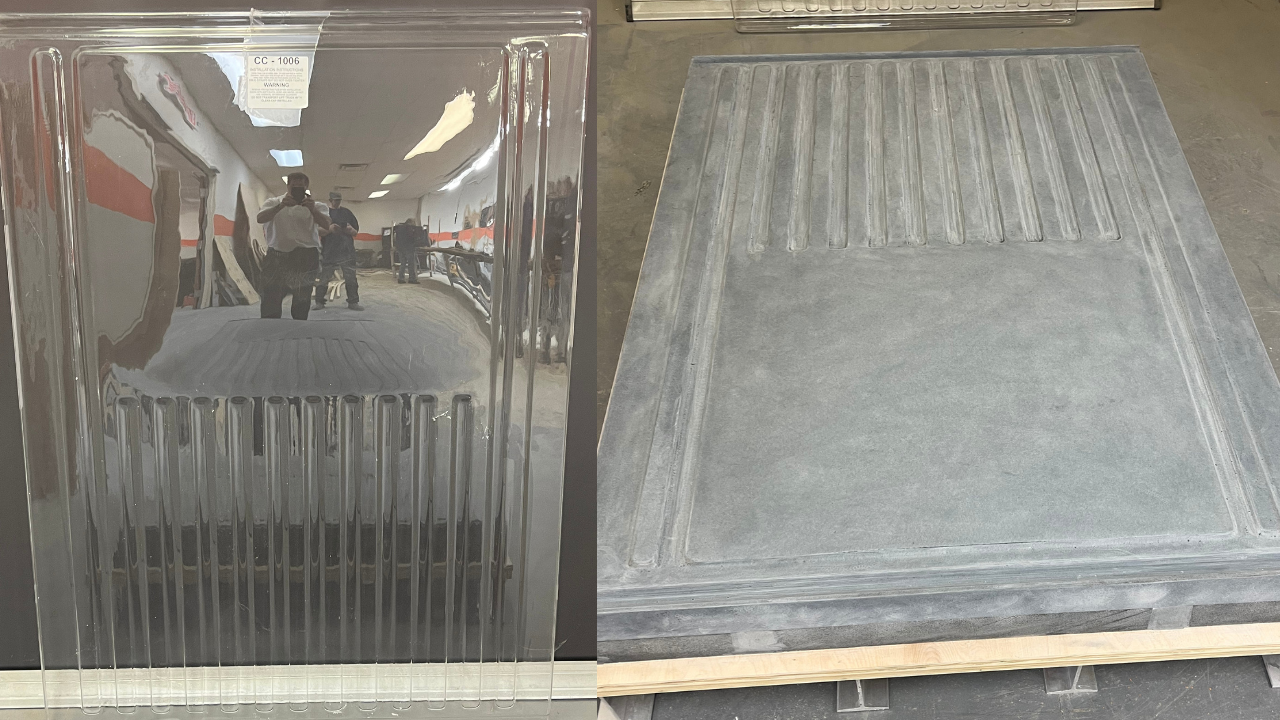

3D Printed Thermoforming Tool For A Forklift Roof Cover

3D Printed Thermoforming Tool For A Forklift Roof Cover This large 39″ x 52″ tool is a 3D printed thermoforming tool to ...

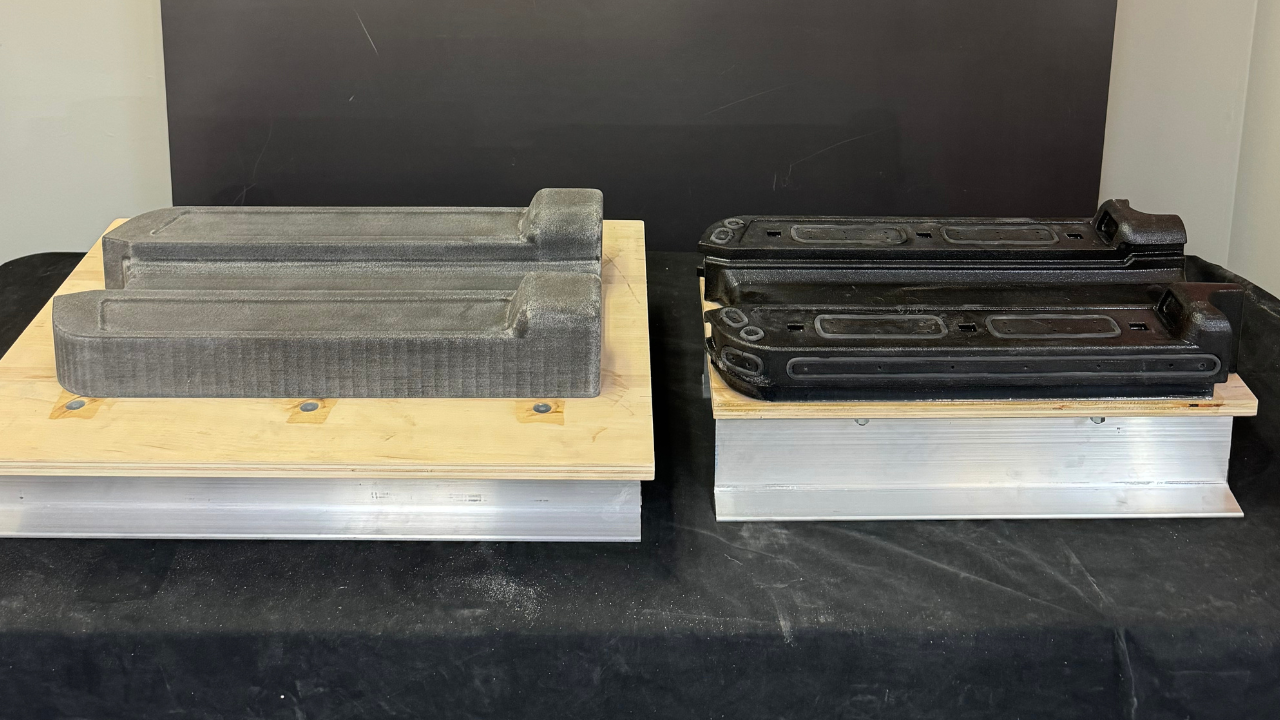

2 Out 3D Printed Vacuum Forming Tool And 2 Out CNC Trim Tool

2 Out 3D Printed Vacuum Forming Tool And 2 Out CNC Trim Tool These tools are a 2 out 3D printed vacuum forming tool and a 2 out trim ...

Reverse Engineering Tools From a Fiberglass Part

Tool Time With Darrell Reverse Engineering Tools From A Fiberglass Part In this episode of ‘Tool Time With Darrell’, President & ...