Vacuum Forming with 3D Printed Tooling

Additive manufacturing has completely changed the way thermoformers – and OEMs – view tooling, in terms of production time, cost and quality. When compared to traditional metal tooling, Catalysis can 3D print tooling in half the time for half the cost while maintaining the same level of quality. Not only that, but 3D printing allows for the design of more complex tooling or low-to-medium volume production parts, removing constraints inhibited by traditional tooling design.

Benefits Of Catalysis 3D Printed Vacuum Forming Tooling

Catalysis 3D printed vacuum forming tooling is transforming the thermoforming industry as we are providing cost and production time savings. This is because our 100% porous build allows for a better quality part, tools are made from a non-conductive material (so no cooling is required), the fully isotropic build avoids any delamination to the tool and light sand blast finish (100RA) eliminates A-side witness marks. The quality of the tool has allowed the highest production project to run for 4,500 parts (.187″ ABS).

- 100% porous structure pulls a better quality part faster

- Made from a non-conductive material so no cooling is required

- Fully isotropic build avoids any delamination

- Light sand blast finish (100RA) eliminates A-side witness marks

- Highest production project ran 3,500 parts (.187″ ABS)

Manufactured in half the time & half the cost of traditional metal tooling

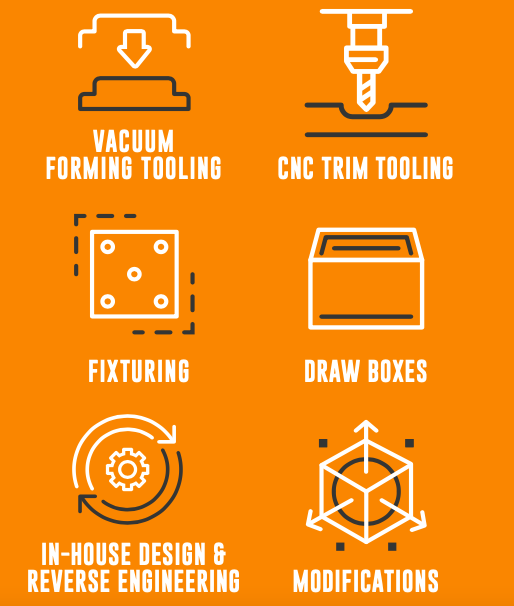

Our technology has allowed us to truly be a One-Stop-Shop for all of your tooling needs

Compared to Conventional Tooling Methods

Metal Vacuum Forming Tool

- Typically manufactured with solid billet or casting

- Process can be very time consuming

- Expensive tooling costs

Ren / Wood Board

- Limited production volumes

- Tool delaminates

- Unable to keep optimal tool temperature