09 Apr 3D Printed Thermoforming Tool For A Forklift Roof Cover

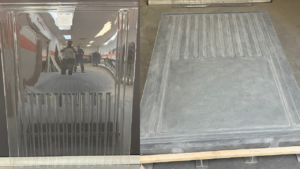

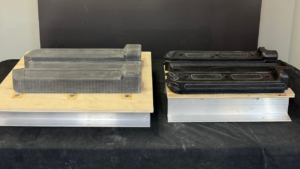

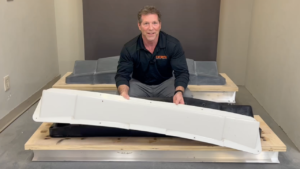

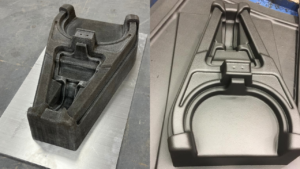

3D Printed Thermoforming Tool For A Forklift Roof Cover This large 39″ x 52″ tool is a 3D printed thermoforming tool to make polycarbonate parts for a forklift roof cover. The tool has a secondary coating for class A ...