31 Oct 3D Printed Vacuum Forming Tool And Trim Tool with A Unique Design

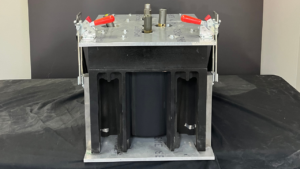

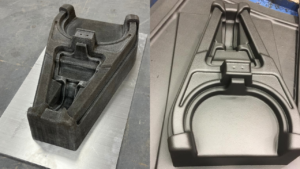

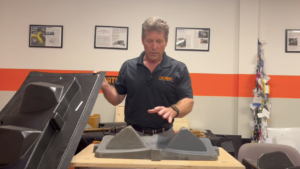

3D Printed Vacuum Forming Tool and An Adjustable Trim Tool These are 3D printed vacuum forming and trim tools, manufactured & delivered together in 3 weeks. The trim tool is a unique Catalysis design, which enables 1 tool to ...