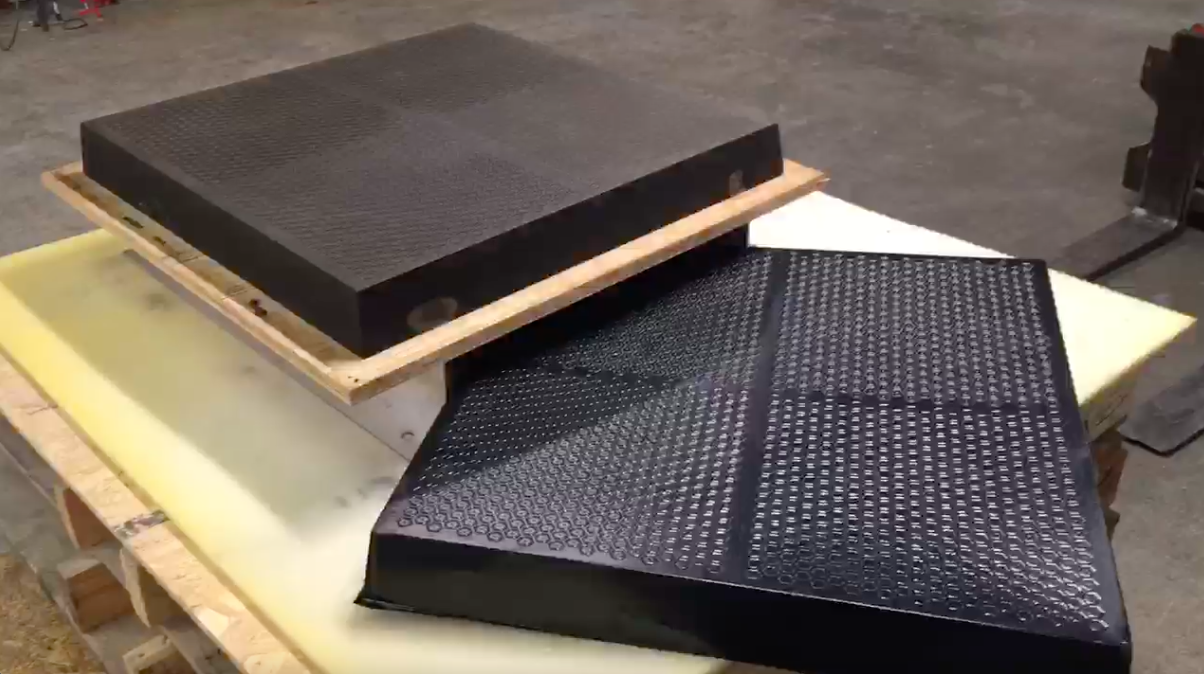

Did you know that we don’t drill holes in our tools?

That’s correct! Our tools don’t have any vacuum holes. With no vacuum holes, we are able to vacuum over the entire tool surface, resulting in better part quality.

How does this work?

The parts pull faster & over 100% of the part surface, so there’s less chance for chill lines. If you have holes, there’s more chance for chill lines. Nobody wants that.

If you can have a part with no chill lines, why not go with that option?

“I was a machinist for 30 years and this tool would have taken hours to make on a mill & cost over $10,000. Using a Catalysis FX™ vacuum forming tool, we were able to get better vacuum on our tool for a fraction of the cost and time. Since joining Catalysis, I haven’t even touched a mill!” – Darrin Love, Manufacturing Manager