Catalysis Additive Tooling has had a very eventful year! From announcing collaborations, various shows and conferences, completing major projects, expanding and being highlighted in magazines, this has been a year worth revisiting. We wanted to take the time to highlight some of our most memorable moments from this year.

Announced Collaboration with ExOne

We were very excited to announce that we were collaborating with ExOne to complete major projects.

> Click here for more information on this announcement & collaboration.

Attending AMUG with ExOne

Our first show of 2019 was exhibiting in ExOne’s booth at AMUG in April.

X1 25PRO Project

As you might’ve heard, one of our major projects from this year was completing tools for ExOne’s X1 25PRO system. We were able to design & manufacture 18 77″x56″ vacuum formed tools in just 3 weeks!

> Click here to read more about this project.

> Click here to watch a video on the full process.

Feature in 3D Printing Industry

We had the honor of being featured in an article in 3D Printing Industry about our collaboration with ExOne. You can read the article here.

“Catalysis Additive Tooling aims to provide its customers with a complete ‘One Stop Shop’ solution by 3D printing tooling as well as manufacturing parts for customers. With customers in a variety of sectors, including automotive, medical and aerospace, Catalysis has developed tooling and manufacturing processes for metal forming, vacuum forming and plastic injection.”

RAPID Show

One of our most memorable moments this year was seeing our hard work displayed at RAPID. Our team worked hard to support ExOne with building their X1 25PRO machine. We were able to complete 18 large tools in just 3 weeks!

17th Annual Honda LEAN

In addition to being at RAPID, we were also one of the 30 exhibitor invited to attend the 17th Annual Honda Lean Conference.

Additive Manufacturing Media Feature

Over the summer, we were honored to have our tools featured in a Additive Manufacturing Media article/video. This article features a video of Stephanie Hendrixson, Senior Editor discussing the benefits of using 3D Printed tooling to reduce cost & time. She uses some of our tools to explain the benefits of using 3D printed tooling versus conventional tooling methods.

“3D printing can offer a cost-effective alternative to conventionally produced tooling for those processes that depend on it.”

> Click here to read this article

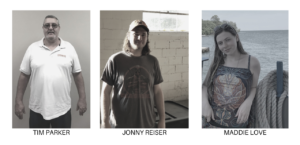

New Team Additions

With our growing number of projects, we were able to grow even more, adding to our hard working manufacturing team!

Additive Manufacturing Cluster Meeting

Towards the end of August, the Catalysis team attended the Additive Manufacturing Cluster meeting in Youngstown, OH. We are always excited to see all the different tooling applications applying AM technologies!

SPE Thermoforming Conference

In addition to RAPID and Honda LEAN, we also attended the 2019 SPE Thermoforming Conference in Milwaukee, WI!

Oak Ridge Labs Display

It is an honor to have the proprietary Catalysis FX™ vacuum forming tooling exhibited at Oak Ridge National Labs MDF Center!

ExOne St. Clairesville, OH Display

We also had our proprietary Catalysis FX™ vacuum forming tool in displayed in ExOne’s St. Clairsville, Ohio facility.

Supporting Penn College in Senior Research project with Humtown Products

Pennsylvania college of Technology is renowned in their thermoforming research. The project objective is to quantify the forming characteristics of forming the same part using a male and female forming tool.

2nd Additive Manufacturing Media Feature (of 2019)

This article focused on the project with ExOne on the X1250 PRO.

“Accelerated timelines, fast design changes and low volumes — in many ways, 3D printing is the right market for 3D printing. ExOne’s newest generation of machines includes parts vacuum formed on 3D printed tools developed by Catalysis Additive Tooling.”

> Click here to read this article.