Tool Time With Darrell

3D Printed Foam Part Manufacturing Tooling

In this episode of ‘Tool Time With Darrell’, President & CEO Darrell Stafford is discussing the many benefits of using 3D printing to make tooling to manufacture foam seating for automotive markets.

Why do you want to use a 3D printed tool for foam part manufacturing?

-

Significant cost and time reduction compared to aluminum tooling

-

Perfect for prototype and low to medium volume production

-

Complete tool heating system

-

Integral magnets

-

Standoff brackets for wire frame

-

Venting features

CLICK THE LINK BELOW TO WATCH THE VIDEO!

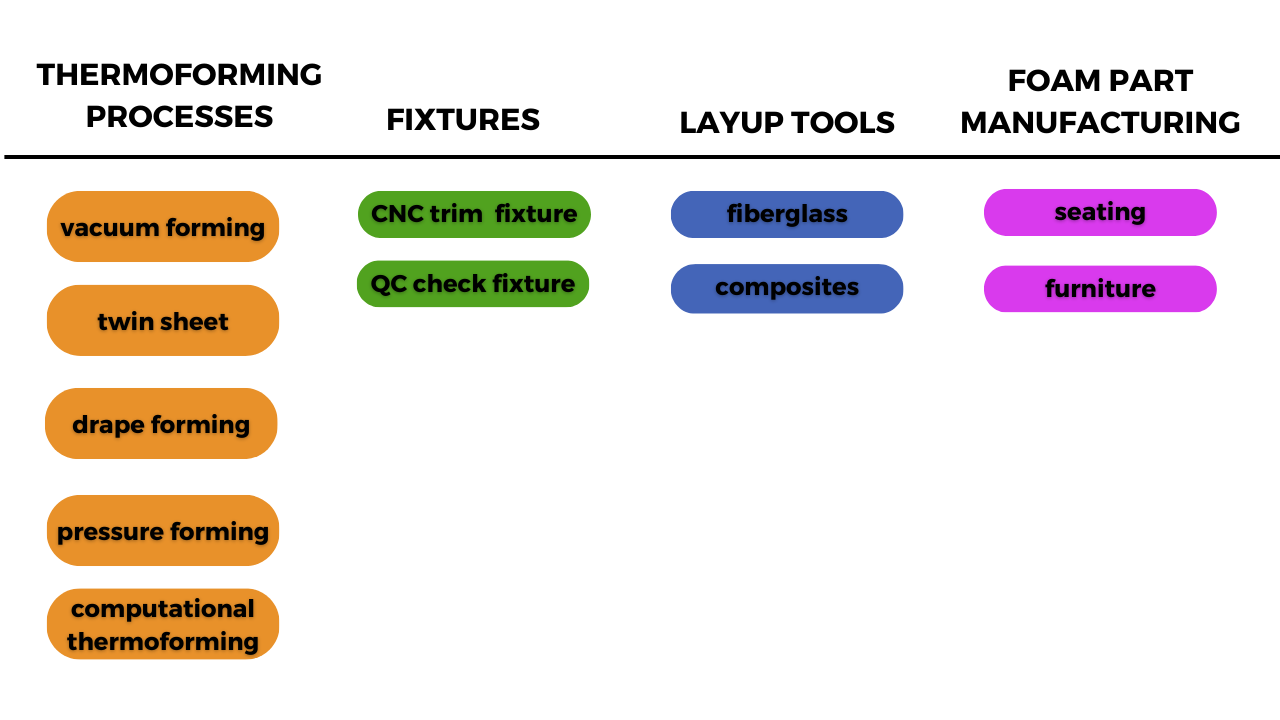

CATALYSIS TOOLING APPLICATIONS

This Is Just One Of Many Examples Of The Benefits Of Utilizing Catalysis For Your Tooling Needs.

If you would like to learn more about our tooling, have any questions or want to request a quote for a project, click the link below. We would love to learn more about your business & how we can help you with all of your tooling needs.