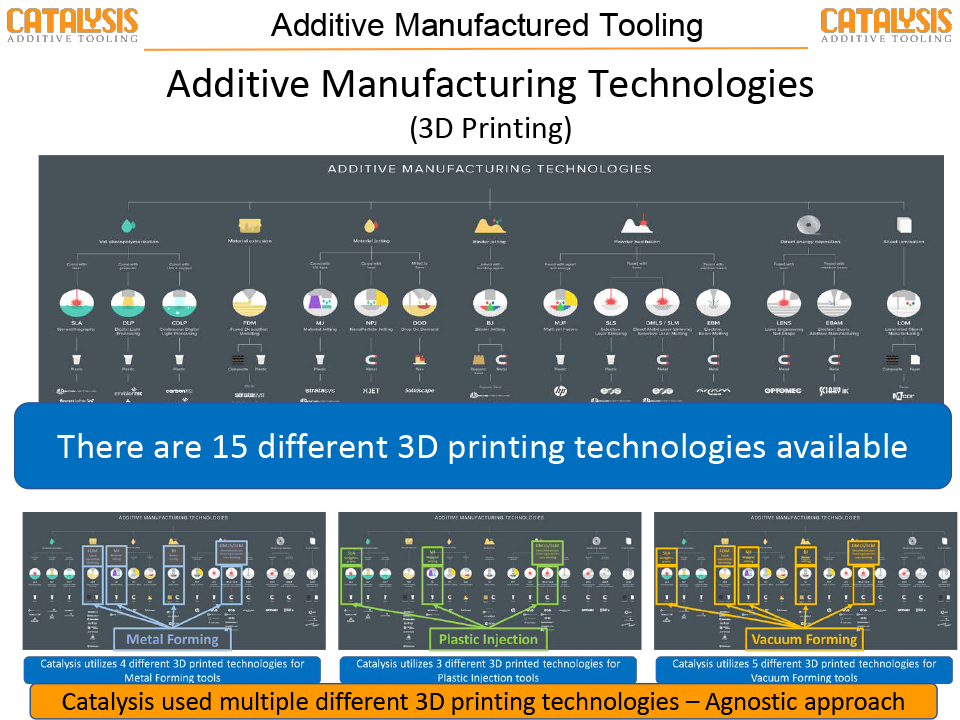

At Catalysis Additive Tooling we take an agnostic approach to 3D Printing. We apply a number of different 3D Printing technologies and select the best technology to meet and exceed our customer needs.

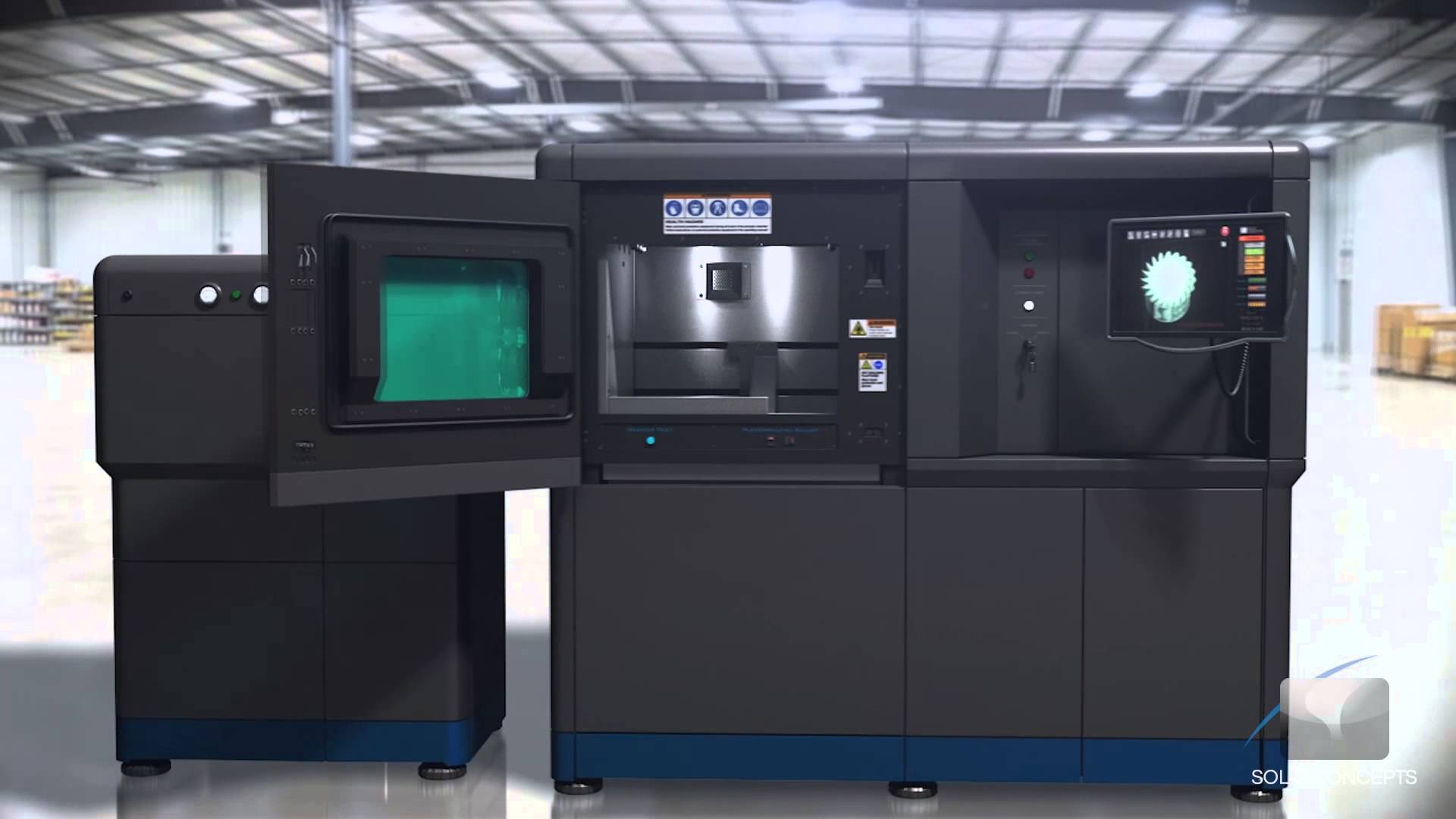

Multi-Jet Fusion (MJF)

3D printing technology utilizes fusing and detailing agents over a powdered nylon 12 building area, with infrared lamps fusing an entire layer in a single pass. This highly efficient method can build functional, geometrically complex parts 80 micron layers at a time – with mechanical properties that rival injection molded parts.

Stereolithography (SLA)

3D printing technology that converts liquid materials into solid parts, layer by layer, by selectively curing them using a light source in a process called photopolymerization.

Selective Laser Sintering (SLS)

Selective laser sintering (SLS) is an additive manufacturing technology that uses a laser to sinter powdered plastic material into a solid structure based on a 3D model.

Binder Jet

Binder Jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. Layers of material are then bonded to form an object.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is a direct metal laser melting (DMLM) or laser powder bed fusion (LPBF) technology that accurately forms complex geometries not possible with other metal manufacturing methods.